- 1. About Roller Shutter Motors?

- 2. Things you need to know about roller shutter motors are as follows:

- 2.1. 1. Tubular Motors for Efficiency:

- 2.2. 2. Choosing the Right Motor:

- 2.3. 3. Drive System Battery Motors:

- 2.4. 4. Considerations in Motor Choice

- 2.5. 5. Common Issues with Roller Shutter Motors:

- 2.6. 6. Versatile 12V DC Motors:

- 2.7. 7. Battery-Powered DC Motors:

- 2.8. 8. Industrial Roller Door Motors:

- 3. Functions and Benefits of Roller Shutter Motor:

- 4. Conclusion

Roller shutter motors, constitute pivotal components in the seamless automation of roller shutters and rolling doors. These motors serve the fundamental purpose of furnishing the requisite power for the systematic opening and closing of these structures. Their role is paramount in ensuring the effortless operation of roller shutters, enhancing convenience and security in various settings.

About Roller Shutter Motors?

Electric roller shutters typically rely on a reliable 240-volt tubular motor, ensuring efficient and long-lasting operation. While some shutters use battery or solar power, the majority utilize these electric motors for their convenience and performance. They can be easily controlled through remote controls, wall switches, or smart devices, providing seamless automation for enhanced security and comfort.

Things you need to know about roller shutter motors are as follows:

1. Tubular Motors for Efficiency:

The utilization of compact and effortlessly installable tubular motors stands out as a prevailing trend in the realm of roller shutter technology. These motors, known for their efficiency, contribute significantly to the streamlined functionality of roller shutters. However, it is imperative to acknowledge that, akin to any mechanical system, these tubular motors are susceptible to malfunctions or wear over time. In such cases, the essentiality of replacement emerges as a critical factor to maintain the overall smooth functioning of the entire system.

2. Choosing the Right Motor:

The meticulous process of selecting the most fitting motor for roller shutters involves a nuanced consideration of several factors. Weight capacity and compatibility with the control system take precedence in this decision-making process. Achieving optimal and effective operation necessitates a thorough evaluation of these factors to ensure that the selected motor aligns seamlessly with the specific requirements and characteristics of the roller shutter system.

3. Drive System Battery Motors:

Three battery motors – The OZRoll Drive System Battery Motors, comprising the T20, T35, and L10 models, represent a sophisticated array of options tailored for diverse purposes. Each model is meticulously designed with specific functionalities and varying weight capacities, offering a spectrum of choices to cater to the unique needs of different roller shutter installations. The T20, with its doubled lifting capacity compared to the L10 motor, is particularly noteworthy for its compatibility with both ODS and E-Series Controllers, fitting seamlessly even into compact headbox spaces.

4. Considerations in Motor Choice

The weight of the roller shutter and its compatibility with the control system emerge as critical considerations in the nuanced process of motor selection. The intricacies of these factors contribute significantly to the overall performance and longevity of the roller shutter system. Choosing a motor that aligns with these considerations ensures optimal functionality and a harmonious integration with the control mechanisms in place.

5. Common Issues with Roller Shutter Motors:

Despite their integral role, roller shutter motors are not immune to issues that may arise over time. Wear, suboptimal installation, or faulty components can impede the smooth operation of these motors. Recognizing and addressing these issues in a timely manner is imperative to uphold the efficiency and security that roller shutters are designed to provide. Troubleshooting techniques or, if necessary, the replacement of components, become crucial in maintaining the sustained effectiveness of the roller shutter system.

6. Versatile 12V DC Motors:

The prevalence of versatile 12V DC motors underscores their efficiency and reliability in the domain of motorized roller shutters. These motors find widespread application in both residential and commercial settings, providing a consistent and dependable power source. Their adaptability makes them a go-to choice for various roller shutter installations, contributing significantly to the seamless automation of these structures.

7. Battery-Powered DC Motors:

The advent of battery-powered DC motors addresses scenarios where a constant power source may not be readily available. These motors, powered by batteries, offer an additional layer of convenience, especially in applications such as electric roller shutters and window shutters. Their capacity to operate even during power outages adds an extra dimension of reliability to the functioning of roller shutter systems.

8. Industrial Roller Door Motors:

Engineered explicitly for heavy-duty applications, industrial roller door motors stand out as robust and powerful components. Their design caters to the heightened demands of commercial and industrial settings, where durability and enhanced power are paramount. The increasing popularity of these motors in commercial environments attests to their efficacy in providing heightened convenience and security for larger openings.

Functions and Benefits of Roller Shutter Motor:

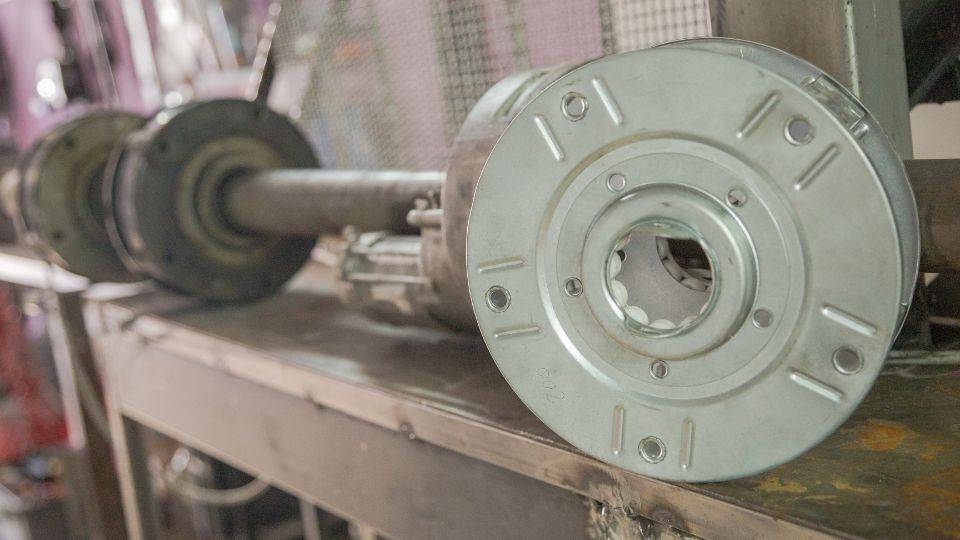

Due to its numerous advantages, residential windows frequently choose roller shutter motors for their operation, which entails the controlled movement of a roller shutter to raise or lower a window. While in the raised position, it maintains a subtle appearance, adding to its appeal for usage at home. It also provides exceptional sound isolation and security. The primary type of roller shutter motor commonly employed is the tubular motor, seamlessly integrated into the roller shutter axle. This motor typically takes the form of a metallic tube featuring a flange at one end.

Powering the roller shutter motor involves two distinct sources: an electric motor and a battery. The electric motor provides the necessary power to operate the motor, which, in turn, controls the movement of the shutter. In most instances, a roller shutter operates with a motor and a full-width roller, interconnected by a shaft and supported by cheek plates. The linkage is facilitated through cables and flanges positioned at each end, with the servo motor typically responsible for the roller shutter’s operation. It is imperative for the motor to be activated for the opening and closing mechanism to function, as the door remains non-operational if the motor malfunctions.

The motor’s role in propelling the roller shutter is facilitated through the utilization of battery power. A cable connects the motor, and the cable’s strength is crucial to bear the weight of the roller shutter. Without a power source, the motor remains non-functional, underscoring the essential nature of a reliable battery. Additionally, the motor must be securely positioned along the track, requiring a stable mounting base for optimal performance. In systems with a servo, the control unit is typically situated at the bottom of the guide.

The connection between the motor and the roller shutter occurs through the shaft. An important consideration is the motor’s susceptibility to overheating, which can lead to a cessation of operations. The motor lacks an automatic shutdown feature based on temperature, necessitating proactive cooling measures before operation. If the temperature exceeds acceptable levels, the motor will automatically disengage. Following the full opening of the shutter, the motor triggers the automatic closure. In the absence of manual intervention to open the door, it will automatically close.

Conclusion

In conclusion, the multifaceted role of roller shutter motors extends across diverse settings, offering tailored solutions for a countless of applications. Whether it be in residential, commercial, or industrial contexts, the effective operating of these motors ensures the seamless operation of roller shutters, contributing significantly to security and convenience. Regular troubleshooting or, when necessary, the safe replacement of components guarantees the sustained effectiveness and security of roller shutter systems over time. The complex interaction of these motors with the broader roller shutter infrastructure underscores their critical importance in the realm of automated security solutions.